Description

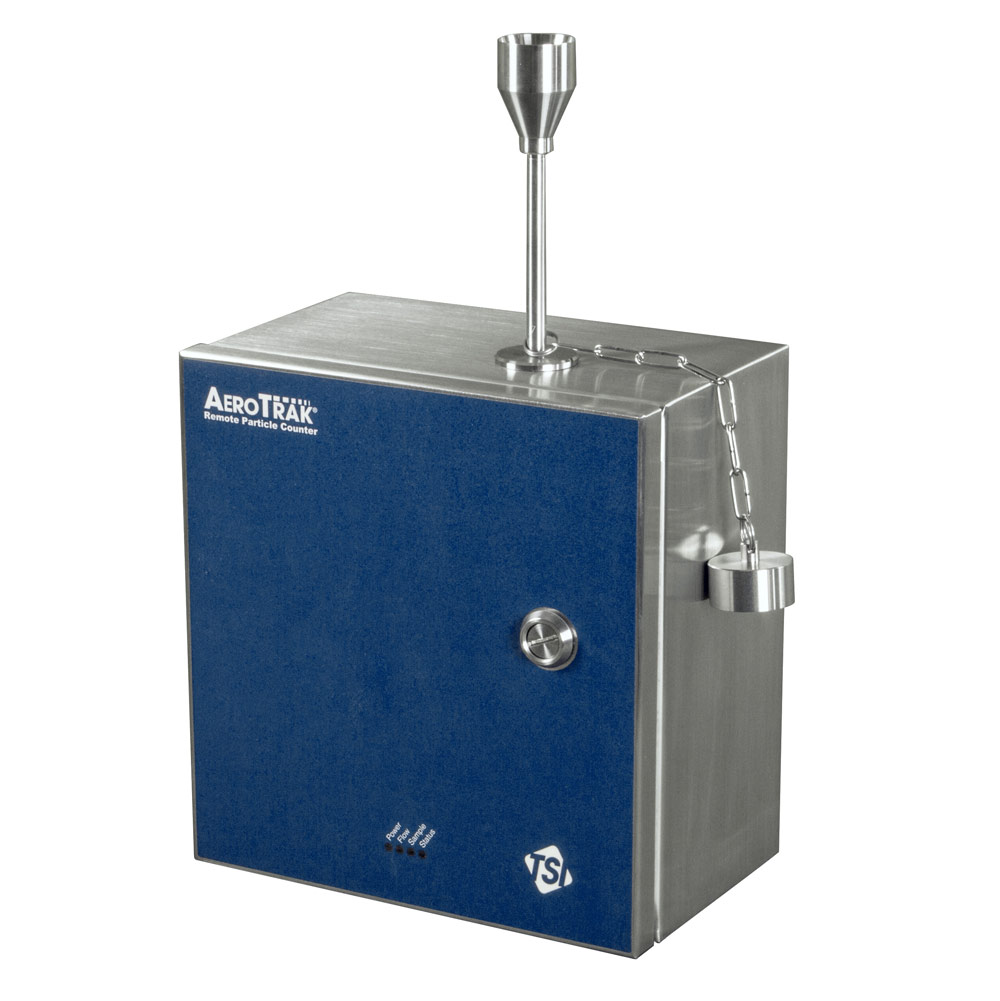

TSI AeroTrak Models 6310, 6510 and 6510-VHP include an integrated clean pump to eliminate the need for an external vacuum source. Four standard analog inputs help to reduce installation and integration costs. Vaporized Hydrogen Peroxide (VHP) resistance and sample inlet capping auto-detect means this instrument is ideal for use in any GMP controlled area where continuous particulate and environmental monitoring is required. Data is output via integrated Ethernet (TCP/IP), serial Modbus RTU communications and 4-20mA analog outputs.

Removing the unique hot-swap combined particle sensor and blower assembly from the mounted enclosure requires no tools, making it quick and easy to maintain. For ease of use, the internal pump automatically stops when the sample inlet probe is capped.

TSI’s optional FMS Buddy Automatic Hot-Standby Monitoring Software adds increased levels of assurance by maintaining full system functionality in the event of a monitoring computer failure. The 3,000 sample record data buffer provides data redundancy, assuring full compliance and peace of mind during an unexpected network failure.

MEETS CURRENT GMP GUIDELINES AND INTERNATIONAL STANDARDS

- 1 CFM (28.3 L/min) flow rate, up to four channels of particle data including 0.5μm and 5μm per EU and US FDA Aseptic Processing Guidelines

- ISO 21501-4 compliant calibration delivers consistent instrument counting and sizing performance

- FMS 5 monitoring software integration enables 21 CFR Part 11-compliant data collection

EASY TO INSTALL AND MAINTAIN

- Eliminates the need for a centralised vacuum system

- Internal blower has no carbon vanes and low heat gain

- Standard four 4-20mA analog inputs reduce environmental sensor integration and installation costs

- Sample inlet capping auto-detect automatically stops the blower and prevents accidental damage

- Model 6510-VHP is resistant to Vaporised Hydrogen Peroxide exposure, enabling use where VHP surface disinfection is utilised

- Ethernet (TCP/IP) and serial Modbus RTU data output enables seamless integration into most software, including TSI’s FMS software

- Hot-swap optical sensor and pump slide out as a single assembly for fast and easy maintenance; no tools required

MONITORING APPLICATIONS

- GMP Controlled Areas

- Isolators

- Restricted Access Barrier Systems (RABS)

- Cleanrooms

- Hospital Pharmacies

- Laboratories

- Industrial

- Aerospace